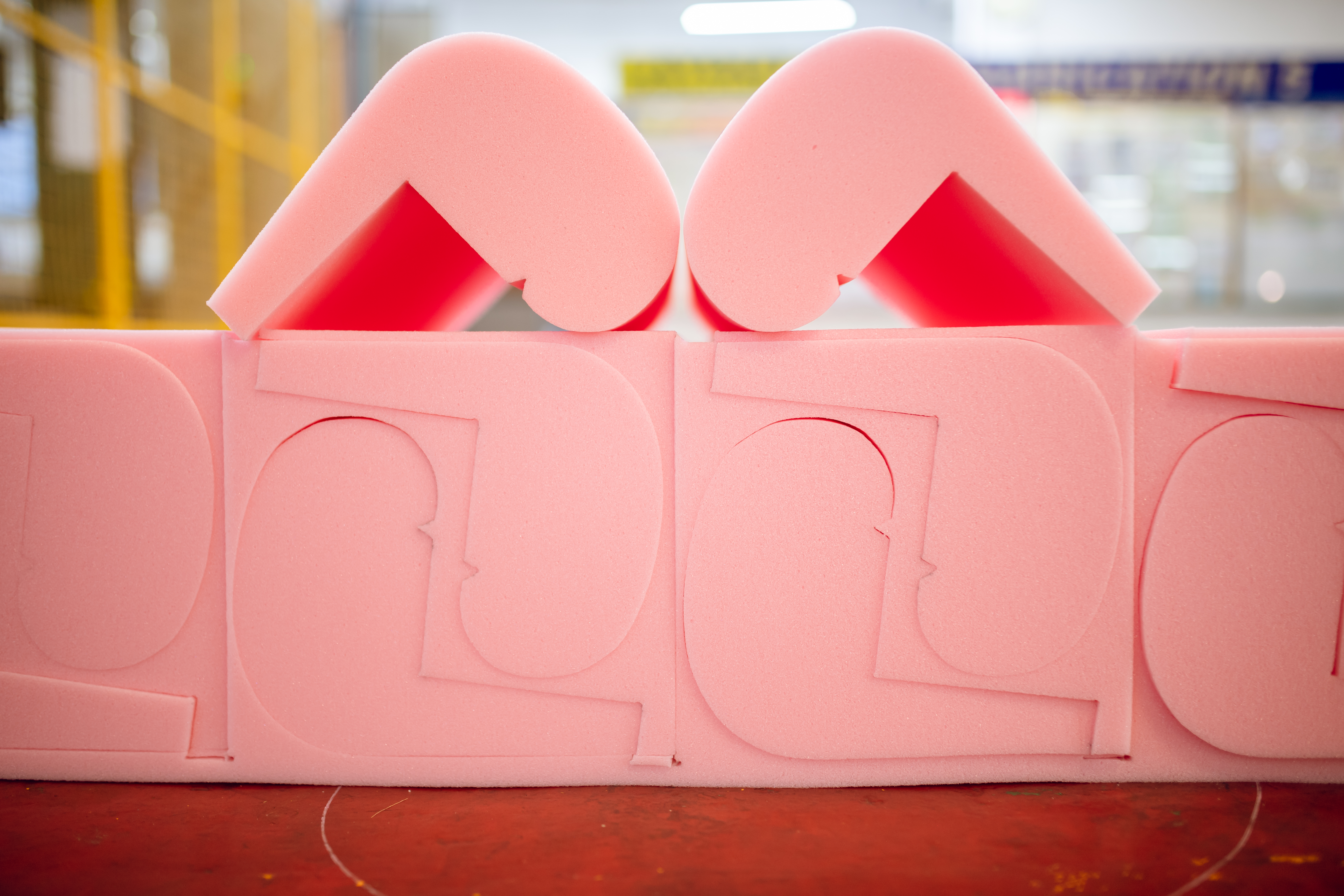

Anti-Yellowing Foam

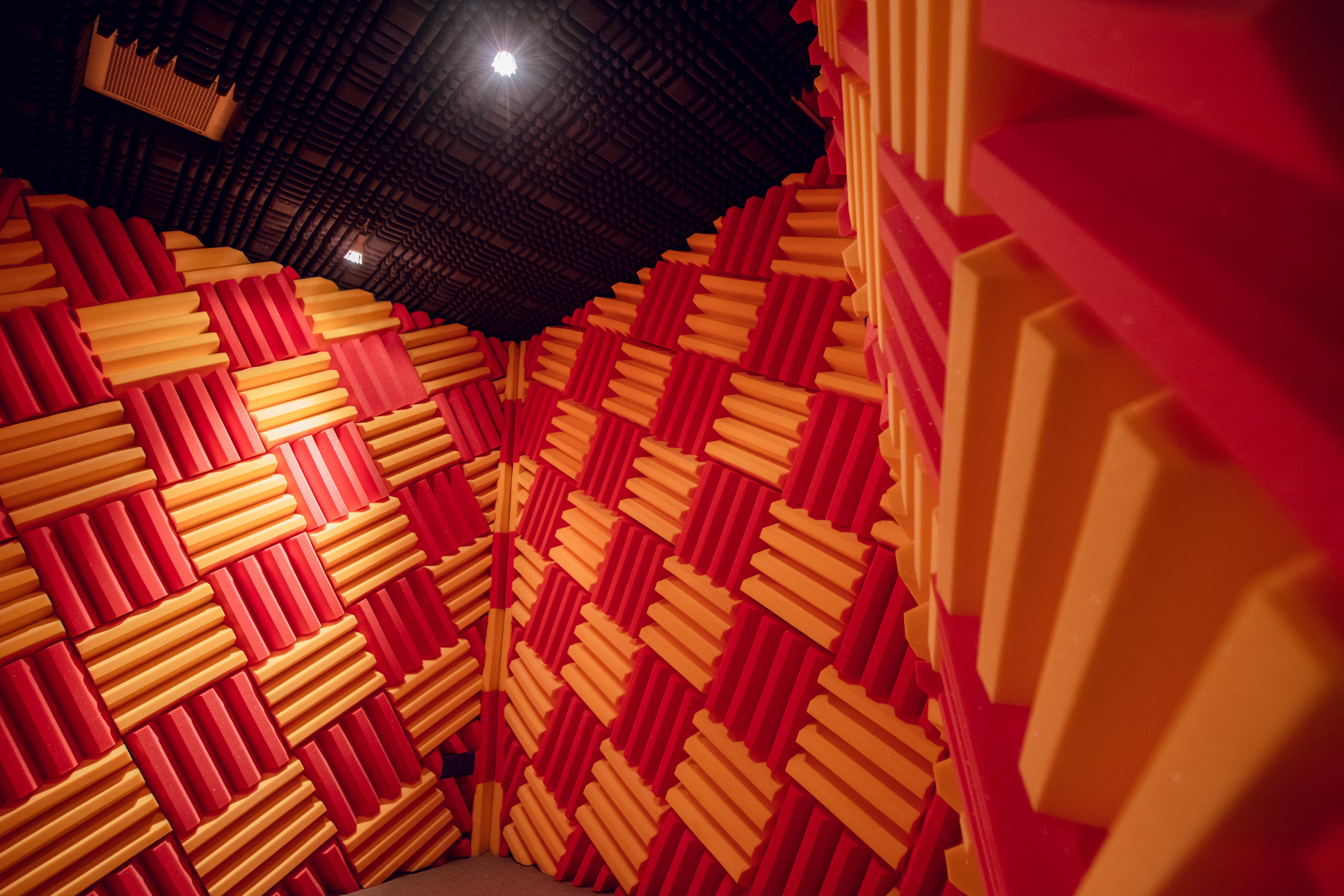

UV-LIGHT DISCOLORATION TESTING METHOD :

Test Method : ASTM D1148-95

- Specimens to be tested for discoloration are placed under a sunlamp bulb contained in test chamber the specimens shall include one or more reference specimens of known discoloration characteristics.

- After exposing the specimens to radiation from the sunlamp for specified perioc of time, the degree of discoloration is rated against the reference standard or the original specimens, or both.

RECOMMENDATION OF YELLOWING FOAM :

Discoloration occurs by forming azo compounds and/or quinonimine from UV light. This is different from breakage of polymer chain so the discoloration will not directly lead to physical property degradation.

Condition for discoloration cause of foam consist of

- Humidity is the direct effect to foam that yellowing faster than normal condition.

- Foam should not be indirect contact with sunlight or lighting system in building store.

- High temperature area such as near the wall or the roof that contact sunlight.

- NOx gas (Gas caused by combustion of fuel)

- Chemical such as glue or substance and other material are attached to foam.

For all of reason it can be avoided by storage foam in dark bag and packaging is not tear. So, these method make the foam yellowing slowly.